Get a quote, configure a custom safety solution or ask a question. We're here to help!

- Spill ContainmentMore …Loading Safety CagesMore …

SafeRack Worldwide

We pride ourselves on one-on-one customer service. When you call SafeRack, we'll be there to answer your questions with a combined experience of 400+ years.

Select your region below.- View Products

- Railcar & Truck Loading Platforms

- Gangways & Loading Ramps

- Stairs, Platforms & Ladders

- Mobile Ladders & Platforms

- Loading Arms & Fluid Transfer

- Safety Gates & Traffic Control

- Aviation & Aerospace Access

- Marine Access & Loading

- Grounding & Monitoring

- Spill Containment

- Loading Safety Cages

- Transloaders & Skids

- Shelters & Canopies

- Fall Protection

- Terminal & Speciality

Home / Industries / Mining & Minerals / Mining & MineralsMining & Minerals

Mining involves moving large volumes of earth to extract valuable resources. Many different types of machines are needed to procure the ore, minerals, and aggregate. These raw materials are used in many industries such as agriculture, chemical, electronics, energy, food, iron and steel, paint, rubber, and medicine to name a few.

Large vehicles are used to transport dirt, coal, limestone, salt, and other minerals that are extracted from the ground. The extra size of the vehicles obviously enables them to carry more product per haul which drives down per load costs. Accessing and maintaining these vehicles can be challenging as their sheer size mean workers are almost always going to be working from height to maintain them.

Surface mining and underground mining vehicles such as LHD loaders, scoops, mining scalers, dinting machines, and rock breakers play pivotal roles in successful mining operations. Workers need safe access and fall protection to keep these machines running and well maintained to ensure operations continue to be productive.

Surface mining – “There are five recognized types of surface mining, each with specific variations depending on the minerals being extracted. These include strip mining, open-pit mining, mountaintop removal, dredging and high wall mining.”

Question, Get a Quote, Live Demo or Request an On-Site Visit

Our experts simplify the complex

View Full TextUnderground mining “When any ore body lies a considerable distance below the surface, the amount of waste that has to be removed in order to uncover the ore through surface mining becomes prohibitive, and underground techniques must be considered. Counting against underground mining are the costs, which, for each ton of material mined, are much higher underground than on the surface. There are a number of reasons for this, not the least of which is that the size of underground mining equipment—because of ground conditions, ore body geometry, and other factors—is much smaller than in the open pit. Also, access is much more limited. All of this means that productivity, as measured in tons produced per worker per shift, can be 5 to 50 times lower, depending on the mining technique, than on the surface. Balanced against this is the fact that underground only ore is mined, whereas in the open pit there are often several tons of waste stripped for each ton of ore.”

Typical Mining Loading Platform

Quote or discuss your installation.

Start by selecting loading application"*" indicates required fields

Below are some of the loading and unloading solutions for illustrative purposes only. Our experts will work with you and your team for a custom solution to suit your needs.

Loading Gangways and Safety Cages

Standard 24” wide access gangway helps improve access and egress to and from high access points on earth movers. It will improve productivity and safety. Powered gangway solutions are also an option to further increase ergonomics, with a choice of hydraulic and pneumatic systems. The gangway can be mounted to a fixed platform system or directly to equipment.

GX FLAT RAMP ACCESS (FRT) GANGWAY

SafeRack’s NEW GX-FRT is a flat ramp model popular with railcars. It features a slip-resistant walk surface and, with the use of the telescoping extension, eliminates gaps on narrow railcars. Learn More

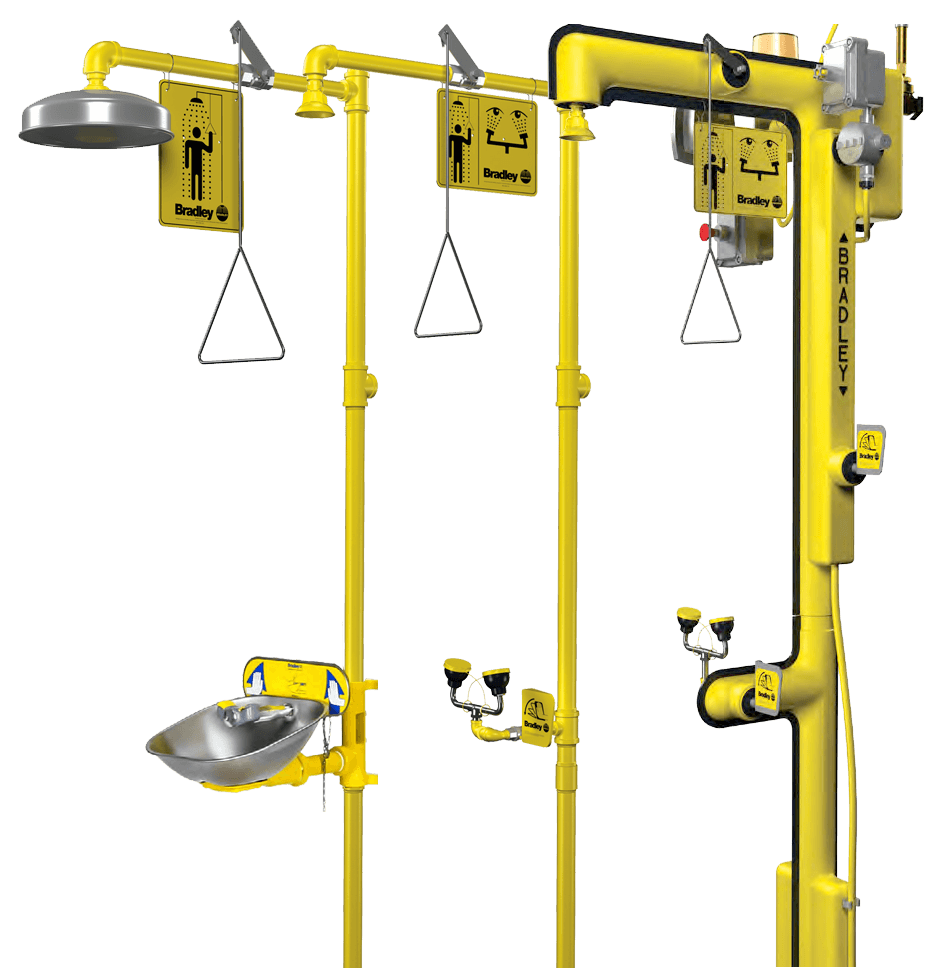

Mining Eye Wash/Drench Showers

ANSI guidelines state that an Eye Wash/Drench Showers need to be located 10 seconds or 55’ (16.8m) from contaminants or hazardous materials.

Eyewash stations need to be on the same horizontal plane with no obstructions.

Therefore, we would propose the installation of a standard combination Drench Shower/Eyewash Unit, which will save limited space and fit easily into any work environment.

Mining Spill Containment

Spill containment pans will be provided at the point of loading operations and is an essential piece of equipment in overall site safety and environmental protection.

Mining Safety Gates

Safety Gates will be installed at the top of stairs and any other openings to ensure operator safety at all times.  YellowGate Safety Gates

YellowGate Safety GatesSafeRack’s line of industrial safety gates is the most flexible product on the market with the ability span openings between 16” and 36” and is field adjustable with nothing more than a wrench. Learn More

Mining Options

- Lighting – Lighting both over and under the platform will be provided. For overcast days or second shift, lighting is essential for improved safety and improved productivity.

- Platform & Canopies – Full platform canopies reduce exposure to the elements and improve the safe and productive loading operation from the operator’s perspective.

- Operator Shelter – Depending on your site requirements, consideration should be given to the requirement of an operator or guard building on the loading platform. This can be customized to meet specific site requirements

- Wheel Chocks – Railcar Wheel Chocks provide fast blocking of all types of railcars and meet OSHA regulations to safely prevent railroad cars from moving during loading or unloading operations. This is a requirement by the Department of Homeland Security

Personal Protective Equipment PPE Requirements

Eye/Face Protection: Wear chemical safety goggles. A face shield (with safety goggles) may also be necessary.

Skin Protection: Wear chemical protective clothing e.g. gloves, aprons, boots. Coveralls or long sleeve shirts and pants in some operations. Wear a chemical protective, full-body encapsulating suit, and self-contained breathing apparatus (SCBA). Suitable materials include: butyl rubber, neoprene rubber, Viton®, Viton®/butyl rubber, Barrier® – PE/PA/PE, Silver Shield® – PE/EVAL/PE, Trellchem® HPS, Trellchem® VPS, Saranex®™, Tychem® BR/LV, Tychem® Responder® CSM, Tychem® TK. The following materials should NOT be used: natural rubber, polyvinyl chloride. Recommendations are NOT valid for very thin neoprene rubber gloves (0.3 mm or less).

Respiratory Protection: Up to 5 ppm:

(APF = 10) Any chemical cartridge respirator with cartridge(s) providing protection against chlorine*; or Any supplied-air respirator*.

*Reported to cause eye irritation or damage; may require eye protection.

APF = Assigned Protection Factor

Recommendations apply only to National Institute for Occupational Safety and Health (NIOSH) approved respirators. Refer to the NIOSH pocket guide to chemical hazards for more information.

Use a local exhaust ventilation and enclosure, if necessary, to control the amount in the air. Consider using a corrosion-resistant exhaust ventilation system separate from other ventilation systems. It may be necessary to use stringent control measures such as process enclosure to prevent product release into the workplace. Use backup controls (e.g. double mechanical pump seals) to prevent the release of this material due to equipment failure. * For illustrative purposes only. Our experts will work with you and your team for a custom solution to suit your needs Customer Reviews

Customer Reviews

5 5Amazing service!

5 5Amazing service!Robust and quality equipment, better customer service than the other fall protection specialists.

By Jeff Kubiak from Nutrien Ag Solutions on 10/2/21 5 5All positive experiences.

5 5All positive experiences.I would recommend those gangways. They work great and bolted up with no issues. John Bast responded immediately – all positive experiences.

By Rick Sturgeon from Kerman Ag Resources on 12/23/11 5 5I’ve never had such an excellent support from a supplier!

5 5I’ve never had such an excellent support from a supplier!Wow, it’s exactly the way how you deserve to get the business.

By Frank Van Den Adel from Nedelko on 10/4/21 4 5The product looks great.

4 5The product looks great.Scott Hite was very responsive. The product looks great.

By Jeff Rhude from Milk Specialties on 12/19/10 5 5We are very satisfied with our Machine Guarding Components from SafeRack

5 5We are very satisfied with our Machine Guarding Components from SafeRackThank you for the great service, and quick delivery.

By Ethan Eichelberger from Recycling Equipment, Inc on 3/9/20 5 5Better fall protection for our staff.

5 5Better fall protection for our staff.Safety, safety, safety. Good experience with Ike in Customer Service getting the missing hardware corrected swiftly. Great product – it has my recommendation.

By Buddy Sallada from Brenntag NE on 1/10/19Is your plant or facility compliant with ANSI, OSHA, and local safety codes? We can help!

EMERGENCY EYEWASHES / SHOWER EQUIPMENT AND THE ANSI/ISEA Z358.1 – 2014 STANDARD

Are you aware that ANSI guidelines state that Eye Wash/Drench Showers need to be located 10 seconds or 55′ from contaminates or hazardous materials and located on the same horizontal plane, with no obstructions? If bottom loading/unloading, an additional shower should be located at grade as well. SafeRack provides the above equipment plus much more needed to keep employees safe and expedite bulk chemical loading and unloading.

MSHA Regulation Experts – Does your existing access, work stations, and bulk loading/inspection stations meet MSHA’s latest requirements? SafeRack’s professional technical sales consultants are available to meet with your team to make recommendations to keep your facility in front of MSHA’s ever-changing country and region-specific standards and regulations, including lifeline and trolley beam fall arrest systems, metal stairs, crossovers, and access platforms.

Why SafeRack?

The SafeRack approach is a collaborative one. Let’s call it The SafeRack Way. We have, over many years amassed a great deal of experience and understanding of the safety aspects involved in loading road tankers and railcars, as well as the behavioral habits of the operators.

The SafeRack approach is a collaborative one. Let’s call it The SafeRack Way. We have, over many years amassed a great deal of experience and understanding of the safety aspects involved in loading road tankers and railcars, as well as the behavioral habits of the operators.

Quick Quote 866-761-7225

LET US DESIGN YOUR SOLUTION TODAY

Our innovative tools provide 3D visualizations and accurate quotes in minutes.

Get Help NowOrder Now 866-761-7225

Questions or Need a Quote?

Chat live with a knowledgeable and friendly safety expert now.

Bob Kashtan

Located in South Carolina

Joey Robinson

Located in South Carolina

Caelin Lacy

Located in South Carolina

Katie Kelly

Located in South Carolina

Amber Graham

Located in South Carolina

YellowGate Safety Gates

YellowGate Safety Gates

The SafeRack approach is a collaborative one. Let’s call it The SafeRack Way. We have, over many years amassed a great deal of experience and understanding of the safety aspects involved in loading road tankers and railcars, as well as the behavioral habits of the operators.

The SafeRack approach is a collaborative one. Let’s call it The SafeRack Way. We have, over many years amassed a great deal of experience and understanding of the safety aspects involved in loading road tankers and railcars, as well as the behavioral habits of the operators.