It’s reported that workplace injuries cost the automotive manufacturing industry more than $1 Billion each year. However, utilizing the cost-effective safety solutions from SafeRack can help your company avoid downtime and unnecessary costs. With tailored solutions, such as ErectaStep, RollaStep, and PerfectaStep, you can easily improve worker safety and efficiency by eliminating dangerous climbing and wasteful walking.

If you’ve ever been to a manufacturing plant, it’s not hard to see the risks involved in everyday operations. Whether your employees are working on the assembly line or moving heavy parts around on forklift loading ramps, there is always a chance that something can happen and someone will be injured. It doesn’t take much for an accident like this to occur – even one little slip-up could lead to high costs of work injury lawsuit settlements or OSHA penalties down the line.

Fortunately, there are many ways to protect your employees and reduce risk in the workplace – including work platforms and stairs from SafeRack, which can help prevent accidents due to height differences in fleet management, maintenance, or servicing.

Safer working conditions are not always possible, but it is essential to avoid wearing unsuitable clothing when performing a task. For example, if you’re climbing ladders or moving heavy items, make sure that your shoes have rubber soles, so your feet don’t slip from the ladder rungs and grip well on slippery surfaces. It’s also advisable to wear gloves in case of cuts and keep an eye out for any hazards nearby. Spills can cause serious injury as they generate debris which will fly up into contact with whatever surface they come off onto while exiting the container until gravity brings them back down again!

According to a PubMed study, the most common injuries in the automotive industry were sprains/strains (39% of total), followed by lacerations at 22%, and contusions at 15%.

At the end of every workday, every facility/operations manager wants to know if they maximized productivity and minimized risk. That’s where we come in. We specialize in designing safety systems for all industries so that workers are free from injury or death on the job site. Saferack can:

- Protect your automotive workers from the dangers of falling, sprains/strains, and concussions with our fall protection and lifeline cable arrest systems

- Reduce the risk of loss of limbs and lacerations with machine guarding gates

- Improve your bottom line by implementing other Saferack safety solutions throughout your business

Whether it is a crossover, fall protection system at your loading dock, mobile work platforms, or any other type of hazard mitigation equipment – our engineers can design what best suits your needs while also considering factors such as cost and time-to-market pressures. And because these engineering solutions are built into our software platform, customers will receive 3D drawings with their quotes within minutes. If you’re looking for ways to improve employee safety at your company, contact us today! You can also find more information on our website or by giving us a call.

Is your plant or facility compliant with ANSI, OSHA, and local safety codes? We can help!

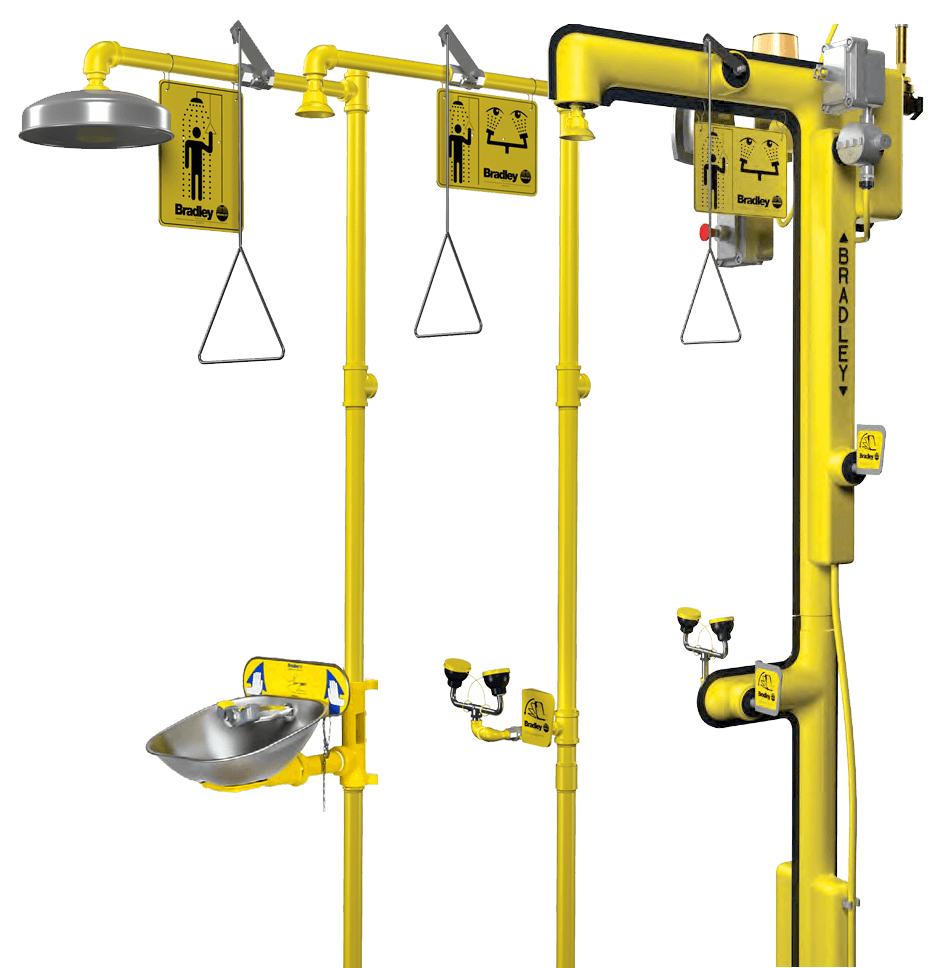

EMERGENCY EYEWASHES / SHOWER EQUIPMENT AND THE ANSI/ISEA Z358.1 – 2014 STANDARD

Following eye contact, you must start washing with water immediately to prevent permanent damage. In the event of skin contact, you must start washing with water immediately to prevent slow-healing chemical burns.

Are you aware that ANSI guidelines state that Eye Wash/Drench Showers need to be located 10 seconds or 55′ from contaminates or hazardous materials and located on the same horizontal plane, with no obstructions? If bottom loading/unloading, an additional shower should be located at grade as well. SafeRack provides the above equipment plus much more needed to keep employees safe and expedite bulk chemical loading and unloading.

OSHA Regulation Experts – Does your existing chemical safety equipment or chemical loading systems meet OSHA’s latest requirements? SafeRack’s professional technical sales consultants are available to meet with your team to make recommendations to keep your facility in front of OSHA’s ever-changing country and region-specific standards and regulations, including lifeline and trolley beam fall arrest systems, metal stairs, and access platforms.