Get a quote, configure a custom safety solution or ask a question. We're here to help!

- Spill ContainmentMore …Loading Safety CagesMore …

SafeRack Worldwide

We pride ourselves on one-on-one customer service. When you call SafeRack, we'll be there to answer your questions with a combined experience of 400+ years.

Select your region below.- View Products

- Railcar & Truck Loading Platforms

- Gangways & Loading Ramps

- Stairs, Platforms & Ladders

- Mobile Ladders & Platforms

- Loading Arms & Fluid Transfer

- Safety Gates & Traffic Control

- Aviation & Aerospace Access

- Marine Access & Loading

- Grounding & Monitoring

- Spill Containment

- Loading Safety Cages

- Transloaders & Skids

- Shelters & Canopies

- Fall Protection

- Terminal & Speciality

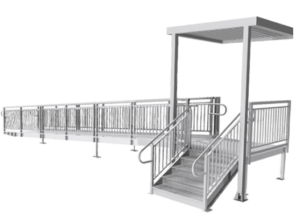

Home / Industries / Generator MaintenanceGenerator Platform, Stairs and Safety Equipment

- Prefabricated industrial-grade aluminum.

- Save time and money with our modular and bolt-together patented design.

- No welding and time-consuming engineering needed.

SafeRack has successfully installed safety solutions in power plants throughout North America. We understand that power generation plants pose an array of workplace dangers and keeping your workers safe is a constant challenge, as a mistake at your plant can easily prove fatal.

SafeRack has successfully installed safety solutions in power plants throughout North America. We understand that power generation plants pose an array of workplace dangers and keeping your workers safe is a constant challenge, as a mistake at your plant can easily prove fatal.Regardless of the specific equipment, you’re almost always going to need to get up to or on top of something, and that’s where SafeRack comes in. SafeRack can support you with a broad range of safety solutions, including access stairs, mobile stairs, access platforms, safety gates, emergency drench showers & eyewash stations, spill containment, and grounding devices.

Generators can give years of reliable service, but that’s typically only possible with regular maintenance. The following items need to be checked in line with on-site TPM (Total Productive Maintenance) procedures:

- Air filter inspection

- Oil change

- Fuel level check

- Cooling system check

- Belt inspection

- Battery check

- Replacement of worn parts

Question, Get a Quote, Live Demo or Request an On-Site Visit

Our experts simplify the complex

“As subject matter expert, I’ll leverage my years of experience as your personal consultant throughout the project to ensure you get a world-class solution.”

Larry Foley-Distribution Center Market SpecialistContract# 47QSAWA19D0085View Full Text

Solutions for any size project

Whether it’s a large industrial turbine or a small commercial backup generator, SafeRack’s product solutions are prefabricated, with many projects only requiring a few hours and nothing more than a wrench. Work with our team of experts for more custom or complicated solutions. Because we utilize a state-of-the-art configurator tool, you can view accurate quotes and custom detailed drawings in minutes.

Case Study – Elevated Generator Platform

- Customer’s diesel generator had a wood generator platform that didn’t meet OSHA regulations

- Using in-stock ErectaStep components, the wood platform was replaced with minimal delivery and installation time.

- This generator platform bolted together and didn’t require special tools, equipment, or welding.

- The solution provided needed to be able to support the weight of the generators, as well as withstand winds and other weather conditions.

Case Study – Turbine Generator Platform in China

- Client in China wanted to replace the long-term use of scaffolding with a permanent, OSHA-compliant solution for safe access to their GEC Turbines

- They were looking to reduce the cost of renting scaffolding

- SafeRack was chosen, and the client was delighted with the outcome – Safety and productivity working in harmony

Case Study – Access platform and fall protection for several interior generators

Generators were at height, and while accessible, maintaining them was dangerous and not OSHA compliant. Installing ErectaStep platforms, steps, and rails… increasing efficiency, and safety… and is now OSHA compliant.

Case Study – Access platform and fall protection for several interior generators

A large tire manufacturing plant had to regularly access its heat exchangers. Every 4-6 weeks scaffolding was used to access these heat exchangers for maintenance.

Safe Alternatives to Scaffolding

There are safe alternatives to scaffolding that are automatically OSHA compliant. Modern modular work platforms are constructed to exact standards that give users immediate OSHA compliance. Modular systems are designed to give workers superb fall protection, stable workspaces, and ease of construction. Mobile work platforms and fixed work platforms are perfect for scheduled maintenance projects, manufacturing environments, and production line crossovers.

Scaffolding Rental vs Semi-Permanent ErectaStep Metal Modular Platforms

Eliminate Scaffolding Rental Re-certifications

Renting or leasing typical metal scaffolding for semi-permanent or longer-term applications has many disadvantages and some are just downright UNSAFE if not installed correctly. Not the least of which is that scaffolding must be reinspected and re-certified on a regular basis. Sometimes creating timely delays and costly fines if not performed on time.

Fast Scaffolding Replacement

ErectaStep and RollaStep solutions can serve as an even better alternative to all types of semi-permanent to permanent scaffolding. When comparing the two types of access platforms – rental versus SafeRack variants – it is SafeRack’s solutions that can be more effective in many industrial, plant or warehouse uses.

The Hazards and Downfalls of Scaffolding

- More prone to corrosion, rust, and decay

- Cannot easily reach areas without having multiple support columns

- Fastener joints can easily loosen or break

- Large and unsafe gaps in handrails

- Many components and pieces needed to build even a simple platform

SafeRack Generator Maintenance Products

Generator Maintenance

Performing regular maintenance will ensure your industrial generator will operate reliably, helping your business avoid the financial losses associated with a shutdown.

Now to the tactical application on “how”. That’s going to entirely depend on the manufacturer.

Generators can give years of reliable service, but that’s typically only possible with the proper maintenance. The following items are things that need to be checked at least annually.

Air Filter Inspection

Air Filters can get dirty. Really dirty. And when the filter is loaded with dirt, dust, and other small particulates, it can cause significant damage to the engine. These should be inspected and cleaned regularly. If they are still fouled after cleaning, just replace them. You don’t need the engine gasping for air when it’s running.

Oil Change

If you’ve ever owned anything with an engine, you know how critical this is. Just like a car, a generator engine requires oil, and oil breaks down over time. Regular oil changes are absolutely necessary for the health of your generator engine and should be included in any maintenance plan.

Fuel Level Check

Make sure that you’re using high-quality fuel and make sure you don’t run it down to empty. The bottom of the fuel tank can have water and sediment that will end up being run through the filter which can clog the fuel filter. This could result in unfiltered debris damaging your engine, so try not to run it empty, and make sure you change the fuel filter if it looks to be clogged.

Cooling System Check

A well-maintained cooling system will help keep your generator engine from overheating, which could damage it beyond repair. Check the coolant level and refill as needed. You’ll also want to flush the cooling system entirely at the manufacturer’s recommendation. This will help maintain coolant quality so that your generator gets the maximum benefit.

Belt Inspection

The belts that run the alternator, fan and other parts of your engine can start to wear down over time. This can cause them to warp and crack, and could eventually break entirely. You might even notice strange squealing sounds coming from the belts. These are signs that the belts need to be replaced before they wreak havoc.

Battery Check

Your battery’s connections should be cleaned and tightened to help prevent battery failure. Also, make sure to run the battery for a few minutes to check its operation. If your generator doesn’t start up, it could be a simple battery malfunction or a larger issue with the system, so you should have a qualified technician look it over to determine the root cause of the power failure.

Replacement of Worn Parts

Cracked hoses, corroded connections, and other worn-out parts should be repaired or replaced as soon as possible. Left unaddressed, your generator can become less efficient and experience additional wear and tear, eventually causing a breakdown of your power system.

Quick Quote 866-761-7225

LET US DESIGN YOUR SOLUTION TODAY

Our innovative tools provide 3D visualizations and accurate quotes in minutes.

Get Help NowOrder Now 866-761-7225

Questions or Need a Quote?

Chat live with a knowledgeable and friendly safety expert now.

Bob Kashtan

Located in South Carolina

Joey Robinson

Located in South Carolina

Caelin Lacy

Located in South Carolina

Katie Kelly

Located in South Carolina

Amber Graham

Located in South Carolina