Get a quote, configure a custom safety solution or ask a question. We're here to help!

- Spill ContainmentMore …Loading Safety CagesMore …

SafeRack Worldwide

We pride ourselves on one-on-one customer service. When you call SafeRack, we'll be there to answer your questions with a combined experience of 400+ years.

Select your region below.- View Products

- Railcar & Truck Loading Platforms

- Gangways & Loading Ramps

- Stairs, Platforms & Ladders

- Mobile Ladders & Platforms

- Loading Arms & Fluid Transfer

- Safety Gates & Traffic Control

- Aviation & Aerospace Access

- Marine Access & Loading

- Grounding & Monitoring

- Spill Containment

- Loading Safety Cages

- Transloaders & Skids

- Shelters & Canopies

- Fall Protection

- Terminal & Speciality

Home / Industries / Bulk Chemical Loading / White Liquor HandlingWhite Liquor Handling

White liquor is a strong alkaline solution composed of sodium hydroxide (NaOH) and sodium sulfide (Na2S) in a mixture of hot water. It is used in the first stage of the Kraft process in which lignin and hemicellulose are separated from the cellulose fiber in wood chips for the production of pulp. The white liquor breaks the bonds between lignin and cellulose. It is called white liquor due to its white opaque color.

White liquor also contains minor amounts of sodium carbonate, sodium sulfate, sodium chloride and other accumulated salts and non-process elements. During the cooking process white liquor becomes black liquor and is later sent to the recovery process for further processing into green liquor.

Question, Get a Quote, Live Demo or Request an On-Site Visit

Our experts simplify the complex

View Full TextTypical White Liquor Loading Platform

Quote or discuss your installation.

Start by selecting loading application"*" indicates required fields

Below are some of the loading and unloading solutions for illustrative purposes only. Our experts will work with you and your team for a custom solution to suit your needs.

White Liquor Loading Arms

White Liquor is typically loaded into railcars or tank trucks via boom supported aluminum or stainless steel loading arms or chemical hoses with a 150# flange connection. The arm or hose will have a top inlet with a control valve to ensure that it is self-draining after use. If using a by-pass arm, the hose is supported along the length of a mechanical loading arm to improve handling. When loading you can install one liquid and one vapor arm, or a 3” boom supported arm with vapour return hose running along the loading arm. Stainless steel camlok fittings or TODO dry breaks are the preferred coupling methods. For unloading, typically you would use a rigid aluminum or stainless steel self-draining loading arm with EPDM, PTFE or Viton seals. Purge lines can be fitted to the arm, for nitrogen purging. Additional features such as overfill warning indicators or parking latches with proximity sensors can be incorporated into the total system to ensure the arm is correctly stowed when not in use, before any rail movement can occur.

White Liquor Loading Gangways and Safety Cages

A wider access gangway (48″-60″ is preferable) as it helps improve access and egress to and from the vessel. In addition, a wider gangway will reduce the risk of the operator’s PPE getting caught, torn or damaged, and will improve productivity and safety. Powered gangway solutions are also an option, with both hydraulic and pneumatic solutions being commonly used. Each gangway will be fitted with a two-rail safety cage for the railcar crash box. This will be a centered 6’x6’ safety cage to sit directly over the cashbox. This will provide a safe, secure work environment for your operator when connected to their breathing apparatus

GX FLAT RAMP ACCESS (FRT) GANGWAY

SafeRack’s NEW GX-FRT is a flat ramp model popular with railcars. It features a slip-resistant walk surface and, with the use of the telescoping extension, eliminates gaps on narrow railcars. Learn More

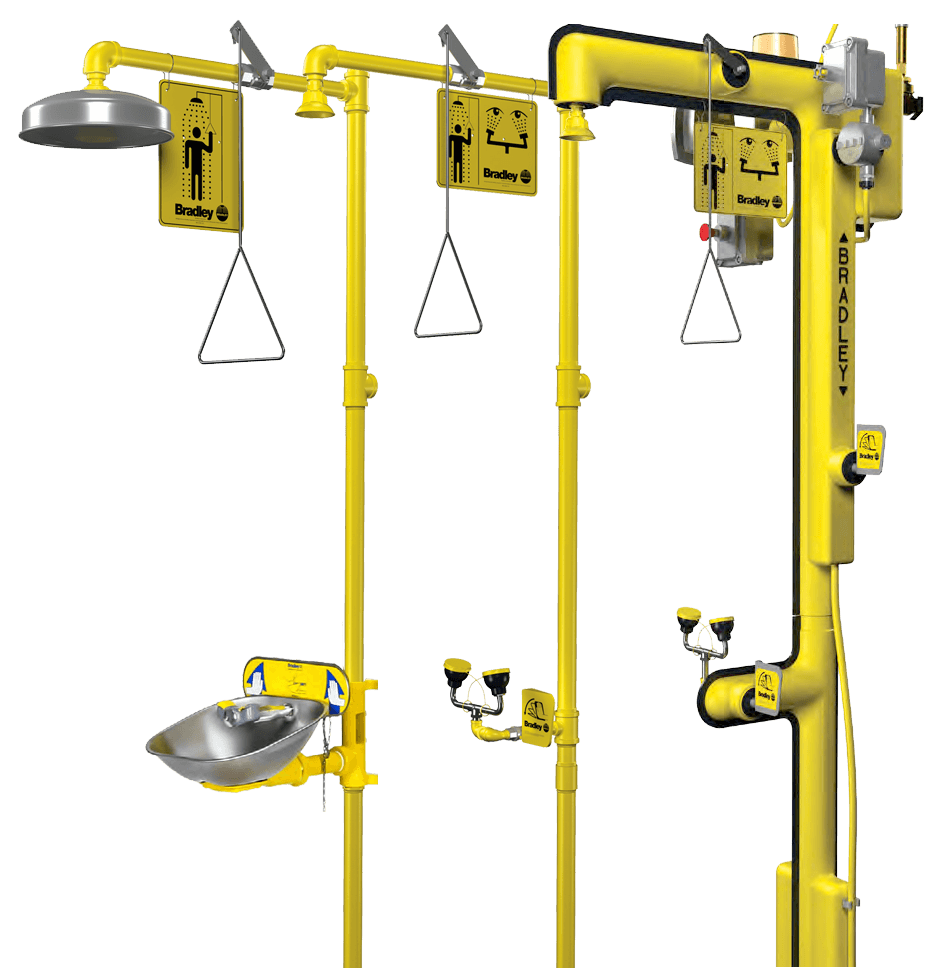

White Liquor Eye Wash/Drench Showers

ANSI guidelines state that an Eye Wash/Drench Showers need to be located 10 seconds or 55’ (16.8m) from contaminants or hazardous materials. Eyewash stations need to be on the same horizontal plane with no obstructions.

Therefore, we would propose the installation of a standard combination Drench Shower/Eyewash Unit, which will save limited space and fit easily into any work environment.

White Liquor Spill Containment

Spill containment pans will be provided at the point of loading operations and is an essential piece of equipment in overall site safety and environmental protection White Liquor Grounding

White Liquor is not normally combustible. However risk of fire does exist in the presence of TRS gases. These fumes are flammable and can be ignited by heat or flame. Vapors have been known to travel back to ignition sources and flashback. - Vehicle grounding and bonding — ensure true grounding before product flow is permitted

- Explosion-proof enclosures — meet or exceed UL, CSA, and Ex requirements

- Non-sparking tools are also recommended while working around this product

White Liquor Safety Gates

Safety Gates will be installed at the top of stairs and any other openings to ensure operator safety at all times.  YellowGate Safety Gates

YellowGate Safety GatesSafeRack’s line of industrial safety gates is the most flexible product on the market with the ability span openings between 16” and 36” and is field adjustable with nothing more than a wrench. Learn More

White Liquor Options

- Lighting – Lighting both over and under the platform will be provided. For overcast days or second shift, lighting is essential for improved safety and improved productivity.

- Platform & Canopies – Full platform canopies reduce exposure to the elements and improve the safe and productive loading operation from the operator’s perspective.

- Operator Shelter – Depending on your site requirements, consideration should be given to the requirement of an operator or guard building on the loading platform. This can be customized to meet specific site requirements

- Wheel Chocks – Railcar Wheel Chocks provide fast blocking of all types of railcars and meet OSHA regulations to safely prevent railroad cars from moving during loading or unloading operations. This is a requirement by the Department of Homeland Security

Personal Protective Equipment PPE Requirements

Mandatory Safety Attire: H2O2 should never come in contact with combustible materials such as cloth or leather. Stepping in even a small puddle of concentrated H2O2 can initiate combustion of leather footwear.

Eye/Face Protection: Wear “snug fitting” chemical safety goggles with a full face shield.

Skin Protection: Wear chemical protective clothing e.g. gloves, aprons, boots. Best practice includes protective chemical, full-body encapsulating suit made of vinyl, neoprene, PVC or polyethylene. As well as, a self-contained breathing apparatus (SCBA). Suitable materials include: butyl rubber, Viton®, Viton®/butyl rubber, Barrier® – PE/PA/PE, Silver Shield® – PE/EVAL/PE, Trellchem® HPS, Trellchem® VPS, Saranex®™, Tychem® BR/LV, Tychem® Responder® CSM, Tychem® TK. The following materials should NOT be used: neoprene, nylon, polyvinyl chloride

Respiratory Protection: Up to 5 ppm:

(APF = 10) Any chemical cartridge respirator with cartridge(s) providing protection against chlorine*; or Any supplied-air respirator*.

*Reported to cause eye irritation or damage; may require eye protection.

APF = Assigned Protection Factor

Recommendations apply only to National Institute for Occupational Safety and Health (NIOSH) approved respirators. Refer to the NIOSH pocket guide to chemical hazards for more information.

Use a local exhaust ventilation and enclosure, if necessary, to control the amount in the air. Consider using a corrosion-resistant exhaust ventilation system separate from other ventilation systems. It may be necessary to use stringent control measures such as process enclosure to prevent product release into the workplace. Use backup controls (e.g. double mechanical pump seals) to prevent the release of this material due to equipment failure. * For illustrative purposes only. Our experts will work with you and your team for a custom solution to suit your needs Customer Reviews

5 5We are very satisfied with SafeRack

5 5We are very satisfied with SafeRackThe people I’ve worked with at this company are quick, friendly, and very reliable. They have beaten the original lead time on orders time and time again.

By Johnson Lauram from Clean Harbors Environmental on 9/18/20 5 5We are very happy with SafeRack!

5 5We are very happy with SafeRack!Great products, great service!

By Bill Lewis from Nutrien Ag Solutions on 5/16/22 5 5Customer service, sales, engineering of the product and the quality was great.

5 5Customer service, sales, engineering of the product and the quality was great.The product was delivered in about 5 days. Customer service, sales, engineering of the product and the quality was great. Delivery was good time-wise and price was less than the other gate openers I priced. I would recommend this product because it makes opening the hopper car gate safe.

By Steven Steinmetz from Dyno Nobel on 2/22/11 5 5Product was delivered in a very timely matter.

5 5Product was delivered in a very timely matter.Product was delivered in a very timely matter and my salesperson was very receptive and responsive to my individual needs.

By Maintenance Team Leader from REG LLC on 7/21/15 5 5The service is what makes the difference.

5 5The service is what makes the difference.The delivery was as promised. Our previous provider fell short on service after the sale, and assistance in providing the correct product for the customer. I am very pleased with the service SafeRack provides. The salesman has been extremely helpful and has gone out of his way to assist in any way possible. Not to be negative, but the fall protection products are comparable, the service is what makes the difference.

By Jerry Hilgendorf from Nustar Logistics, LP on 9/20/13 5 5I would recommend SafeRack based on the customer service.

5 5I would recommend SafeRack based on the customer service.The quoting, payment and delivery process has been very smooth and Claudia was able to accommodate our additional requests. Despite the time difference, she was able to respond to my inquiry in a timely manner. I would recommend SafeRack based on the customer service. The product was delivered within the quoted time.

By Phillip Tam from BioteQ Environmental Tech on 12/23/11White Liquor 101

Things to know about White Liquor

White liquor is an aqueous solution of sodium hydroxide and sodium sulphide used in the Kraft process of making paper and corrugated boxes. Following debarking and chipping of resinous wood, the chipped wood pieces are “cooked” or digested with steam @ approximately 150 psig in the digester with the white liquor solution. After cooking for about 6 hours the lignin binder is dissolved and cellulose fibers, now called pulp or brown stock are separated from the spent cooking liquor (black liquor). The kraft process is associated with strong smelling gases, organic sulphides, which can be an environmental concern.

All the “cooking” liquors in the Kraft paper making process, whether white, green or black tend to be very corrosive and may contain several different toxic and hazardous ingredients. In addition, some of the processes may emit gases, vapors or dust that may be hazardous.

First aid measures for exposure include – removing operators from the source of exposure and into fresh air. Remove contaminated clothing immediately; wash skin thoroughly with soap and water; flush eyes with tepid water for 15 minutes. If ingested do not induce vomiting, but immediately call your local poison control center.

Is your plant or facility compliant with ANSI, OSHA, and local safety codes? We can help!

EMERGENCY EYEWASHES / SHOWER EQUIPMENT AND THE ANSI/ISEA Z358.1 – 2014 STANDARD

Following eye contact, you must start washing with water immediately to prevent permanent damage. In the event of skin contact, you must start washing with water immediately to prevent slow-healing chemical burns.

Are you aware that ANSI guidelines state that Eye Wash/Drench Showers need to be located 10 seconds or 55′ from contaminates or hazardous materials and located on the same horizontal plane, with no obstructions? If bottom loading/unloading, an additional shower should be located at grade as well. SafeRack provides the above equipment plus much more needed to keep employees safe and expedite bulk chemical loading and unloading.

OSHA Regulation Experts – Does your existing chemical safety equipment or chemical loading systems meet OSHA’s latest requirements? SafeRack’s professional technical sales consultants are available to meet with your team to make recommendations to keep your facility in front of OSHA’s ever-changing country and region-specific standards and regulations, including lifeline and trolley beam fall arrest systems, metal stairs, and access platforms.

Installation Gallery

Why SafeRack?

The SafeRack approach is a collaborative one. Let’s call it The SafeRack Way. We have, over many years amassed a great deal of experience and understanding of the safety aspects involved in loading road tankers and railcars, as well as the behavioral habits of the operators.

Experts In Chemical Loading

- Acetic Acid

- Acetic Anhydride

- Acetonitrile

- Acrolein

- Acrylic Acid

- Acrylonitrile

- Aluminum Chloride

- Aluminum Sulfate

- Ammonia

- Ammonium Hydroxide

- Ammonium Nitrate

- Aniline

- Benzene

- Benzyl Chloride

- Bromotrifluoromethane

- Butadiene

- Carbon Dioxide

- Caustic

- Chlorine

- Chloroform

- Chlorosulfonic Acid

- DEF (Diesel Exhaust Fluid)

- Diethylene Glycol

- Dimethylformamide

- Dodecylbenzene Sulfonic Acid

- Ethanol

- Ethyl Acetate

- Ethyl Chloride

- Ethylene

- Ethylene Dichloride

- Ethylene Glycol

- Ethylene Oxide

- Ferric Chloride

- Ferrous Chloride

- Hexane

- Hydrochloric Acid

- Hydrofluoric Acid

- Hydrofluorosilicic Acid

- Hydrogen Cyanide

- Hydrogen Peroxide

- Hydrofluoric Acid

- Hypochlorous Acid

- Isopropyl Acetate

- Liquid Argon

- Liquid Nitrogen

- Liquid Oxygen

- Maleic Anhydride

- MDI

- Methanol

- Methyl Chloride

- Methyl Ethyl Ketone

- Methyl Methacrylate

- Methyl Isocyanate

- Molten Sulphur

- Nitric Acid

- Oleum

- Phenol

- Phosphoric Acid

- Phosphorus Oxychloride

- Phosphorus Trichloride

- Polypropylene

- Renewable Diesel

- Sodium Cyanide

- Sodium Hydroxide

- Sodium Hypochlorite

- Styrene Monomer

- Sulfuric Acid

- Sulfur Dioxide

- Titanium Tetrachloride

- Toluene

- Toluene Diisocyanate

- Turpenitne

- UAN (Urea Ammonium Nitrate)

- UREA

- Vinyl Acetate

- Vinyl Chloride

- Xylene

- Zinc Chloride

- Agro-Chemical

- Specialty Chemical

- Petrochemical

North America’s largest loading terminal

World-leading designer, manufacturer, and installer of truck and railcar loading platforms

As one of the primary railcar loading points, Hardisty is one of the major crude oil hubs in North America and a major origination point of pipelines that export to the United States. SCS was asked to supply and construct a SafeRack crude oil loadout terminal spanning nearly half a mile. The USD Hardisty terminal can load up to two 120-railcar unit trains per day and consists of a fixed loading rack with 62 railcar loading positions enclosed, separate control, operator, and mechanical buildings, as well as a unit train staging area and loop tracks capable of holding multiple unit trains simultaneously. SCS also supplied and installed boom-supported loading arms with supply and vapor management systems.

Quick Quote 866-761-7225

LET US DESIGN YOUR SOLUTION TODAY

Our innovative tools provide 3D visualizations and accurate quotes in minutes.

Get Help NowOrder Now 866-761-7225

Questions or Need a Quote?

Chat live with a knowledgeable and friendly safety expert now.

Bob Kashtan

Located in South Carolina

Joey Robinson

Located in South Carolina

Caelin Lacy

Located in South Carolina

Katie Kelly

Located in South Carolina

Amber Graham

Located in South Carolina

YellowGate Safety Gates

YellowGate Safety Gates