Get a quote, configure a custom safety solution or ask a question. We're here to help!

- Spill ContainmentMore …Loading Safety CagesMore …

SafeRack Worldwide

We pride ourselves on one-on-one customer service. When you call SafeRack, we'll be there to answer your questions with a combined experience of 400+ years.

Select your region below.- View Products

- Railcar & Truck Loading Platforms

- Gangways & Loading Ramps

- Stairs, Platforms & Ladders

- Mobile Ladders & Platforms

- Loading Arms & Fluid Transfer

- Safety Gates & Traffic Control

- Aviation & Aerospace Access

- Marine Access & Loading

- Grounding & Monitoring

- Spill Containment

- Loading Safety Cages

- Transloaders & Skids

- Shelters & Canopies

- Fall Protection

- Terminal & Speciality

Home / Industries / Bulk Chemical Loading / Agro-ChemicalAgro-Chemical

Agro-Chemical Handling Loading Design Experts

SafeRack takes worker safety very seriously and offers a full range of products and equipment designed specifically to reduce the risks associated with agro-chemical transportation while improving loading and unloading throughput.

Operator and Environmental Safety – SafeRack has been providing safe, reliable platforms, handrails, and gangway solutions to the chemical industry for many years. From multifaceted fall prevention retrofits to new builds, SafeRack’s priorities are operator and environmental safety while still focusing on creating an efficient and productive solution that allows a significant return on investment.

Chemical Loading & Handling:

Acetic Acid | Acetic Anhydride | Acetonitrile | Acrolein | Acrylic Acid | Acrylonitrile | Aluminum Chloride | Aluminum Sulfate | Ammonium Hydroxide | Ammonium Nitrate | Aniline | Benzyl Chloride | Bromotrifluoromethane | Caustic | Chlorine | Chloroform | Chlorosulfonic Acid | Diethylene Glycol | Dimethylformamide | Dodecylbenzene Sulfonic Acid | Ethanol | Ethyl Acetate | Ethyl Chloride | Ethylene Dichloride | Ethylene Glycol | Ethylene Oxide | Ferric Chloride | Ferrous Chloride | Hexane | Hydrogen Peroxide| Hydrochloric Acid | Hydrofluoric Acid | Hydrofluorosilicic Acid | Hydrogen Cyanide | Hydrogen Peroxide | Hypochlorous Acid | Isopropyl Acetate | Liquid Argon | Liquid Nitrogen | Liquid Oxygen | Maleic Anhydride | Methyl Chloride | Nitric Acid | Oleum | Phosphoric Acid | Phosphorus Chloride | Phosphorus Trichloride | Polypropylene | Titanium Tetrachloride | Sodium Cyanide | Sodium Hypochlorite | Sodium Hydroxide | Styrene Monomer | Sulfuric Acid | Sulfur Dioxide | Titanium Tetrachloride | Turpentine | Vinyl Acetate | Vinyl Chloride | Zinc Chloride

Petro Chemical

Benzene | Butadiene | Carbon Dioxide | Ethylene | Methanol | Methyl Ethyl Ketone | Methyl Methacrylate | MDI | Molten Sulphur | Phenol | Polypropylene | Toluene | Xylene

Question, Get a Quote, Live Demo or Request an On-Site Visit

Our experts simplify the complex

View Full TextAgro-Chemical Unloading and Loading Products

SafeRack provides the equipment needed to keep employees safe and expedite the loading and unloading of chemicals used in agriculture.

Fertilizers – Organic and Inorganic

Organic fertilizers are made from natural and organic materials—mainly manure, compost, or other animal and plant products. These fertilizers are a great source of nutrients, though there isn’t a measurable amount of any specific nutrients—some bags will print estimates. Organic fertilizers tend to work slowly and over the long-term. It can help to build up your soil over time

Inorganic fertilizers are made of up chemical components that contain necessary nutrients. If you’re looking to give your garden a quick boost, this is likely the best option for you. For successful short-term growth, determine what nutrient your plant needs and use an inorganic fertilizer with nutrients.

There are three (3) primary nutrients found in most commercial fertilizers. Each of these nutrients play a key role in plant nutrition.

1. Nitrogen Fertilizers

Nitrogen is a plan nutrient responsible for growth. This ingredient is useful in fertilizers, particularly during the middle stages of a plant’s lifespan, when it needs encouragement to continue to grow large and stem new leaves. Both organic and inorganic fertilizers have sources of nitrogen in them.

- Calcium nitrate

- Di-ammonium phosphate

- Sodium nitrate

- Ammonium nitrate

- Potassium nitrate

- Urea

- Liquid nitrogen

- Mono-ammonium phosphate

Urea is the most widely used solid nitrogen fertilizer and is usually applied as granules. It can also be mixed with ammonium nitrate and dissolved in water to form urea ammonium nitrate solution. When applied to soil, the urea reacts with water to form ammonia with makes the nitrogen within the fertilizer available to the plants.

MaxRack being installed at Loveland, now Nutrien, in Greenville, MS 2. Phosphate Fertilizers

Phosphorous is a nutrient that plants need continuously. Throughout their lifecycle, phosphorous help to strengthen the root system and stems of a plant. Flowering, seeding, and fruiting can all be improved with phosphorous.

Plants with a phosphorous deficiency will experience stunted growth. Phosphorous is long-lasting and slow acting. Using fertilizer in your soil before planting is generally a good idea.

3. Potassium Fertilizers

Potassium will help your plants to grow deeper and stronger roots. It can also help protect your plants from harm when they are deprived of other nutrients. This nutrient is vital for photosynthesis and has the ability to slow down any diseases that may infect your garden. Potassium fertilizer has a lot of benefits. The when and how of planting this fertilizer will depend on what you’re are planting. When you are using this fertilizer, place it as close to the roots as possible.

- Potassium hydroxide

- Potassium sulfate

- Potassium chloride

- Potassium nitrate

Safety Compliance

Regulation Experts – In many countries, and the United States is no different; the use of agrichemicals is highly regulated. Permits must be obtained before the purchase, and the use of many agrochemicals or significant penalties can result from misuse, including improper storage resulting in spillage. Does your existing safety equipment or loading systems meet current regulations and requirements? SafeRack’s professional technical sales consultants are available to meet with your team to make recommendations to keep your facility in front of the ever-changing country and region-specific standards and regulations, including metal stairs, loading platforms, and platform handrails.

Is your plant or facility compliant with ANSI, OSHA, and local safety codes? We can help!

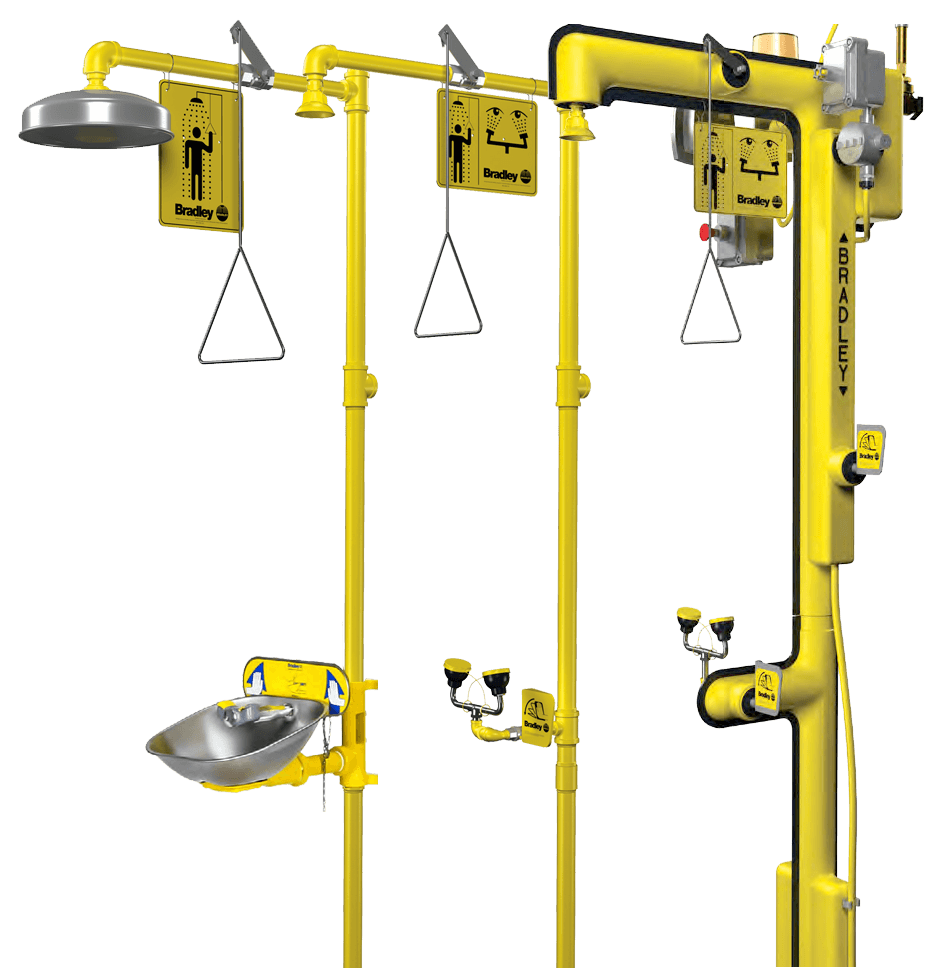

EMERGENCY EYEWASHES / SHOWER EQUIPMENT AND THE ANSI/ISEA Z358.1 – 2014 STANDARD

Following eye contact, you must start washing with water immediately to prevent permanent damage. In the event of skin contact, you must start washing with water immediately to prevent slow-healing chemical burns.

Are you aware that ANSI guidelines state that Eye Wash/Drench Showers need to be located 10 seconds or 55′ from contaminates or hazardous materials and located on the same horizontal plane, with no obstructions? If bottom loading/unloading, an additional shower should be located at grade as well. SafeRack provides the above equipment plus much more needed to keep employees safe and expedite bulk chemical loading and unloading.

OSHA Regulation Experts – Does your existing chemical safety equipment or chemical loading systems meet OSHA’s latest requirements? SafeRack’s professional technical sales consultants are available to meet with your team to make recommendations to keep your facility in front of OSHA’s ever-changing country and region-specific standards and regulations, including lifeline and trolley beam fall arrest systems, metal stairs, and access platforms.

Installation Gallery

Why SafeRack?

The SafeRack approach is a collaborative one. Let’s call it The SafeRack Way. We have, over many years amassed a great deal of experience and understanding of the safety aspects involved in loading road tankers and railcars, as well as the behavioral habits of the operators.

Experts In Chemical Loading

- Acetic Acid

- Acetic Anhydride

- Acetonitrile

- Acrolein

- Acrylic Acid

- Acrylonitrile

- Aluminum Chloride

- Aluminum Sulfate

- Ammonia

- Ammonium Hydroxide

- Ammonium Nitrate

- Aniline

- Benzene

- Benzyl Chloride

- Bromotrifluoromethane

- Butadiene

- Carbon Dioxide

- Caustic

- Chlorine

- Chloroform

- Chlorosulfonic Acid

- DEF (Diesel Exhaust Fluid)

- Diethylene Glycol

- Dimethylformamide

- Dodecylbenzene Sulfonic Acid

- Ethanol

- Ethyl Acetate

- Ethyl Chloride

- Ethylene

- Ethylene Dichloride

- Ethylene Glycol

- Ethylene Oxide

- Ferric Chloride

- Ferrous Chloride

- Hexane

- Hydrochloric Acid

- Hydrofluoric Acid

- Hydrofluorosilicic Acid

- Hydrogen Cyanide

- Hydrogen Peroxide

- Hydrofluoric Acid

- Hypochlorous Acid

- Isopropyl Acetate

- Liquid Argon

- Liquid Nitrogen

- Liquid Oxygen

- Maleic Anhydride

- MDI

- Methanol

- Methyl Chloride

- Methyl Ethyl Ketone

- Methyl Methacrylate

- Methyl Isocyanate

- Molten Sulphur

- Nitric Acid

- Oleum

- Phenol

- Phosphoric Acid

- Phosphorus Oxychloride

- Phosphorus Trichloride

- Polypropylene

- Renewable Diesel

- Sodium Cyanide

- Sodium Hydroxide

- Sodium Hypochlorite

- Styrene Monomer

- Sulfuric Acid

- Sulfur Dioxide

- Titanium Tetrachloride

- Toluene

- Toluene Diisocyanate

- Turpenitne

- UAN (Urea Ammonium Nitrate)

- UREA

- Vinyl Acetate

- Vinyl Chloride

- Xylene

- Zinc Chloride

- Agro-Chemical

- Specialty Chemical

- Petrochemical

North America’s largest loading terminal

World-leading designer, manufacturer, and installer of truck and railcar loading platforms

As one of the primary railcar loading points, Hardisty is one of the major crude oil hubs in North America and a major origination point of pipelines that export to the United States. SCS was asked to supply and construct a SafeRack crude oil loadout terminal spanning nearly half a mile. The USD Hardisty terminal can load up to two 120-railcar unit trains per day and consists of a fixed loading rack with 62 railcar loading positions enclosed, separate control, operator, and mechanical buildings, as well as a unit train staging area and loop tracks capable of holding multiple unit trains simultaneously. SCS also supplied and installed boom-supported loading arms with supply and vapor management systems.

Quick Quote 866-761-7225

LET US DESIGN YOUR SOLUTION TODAY

Our innovative tools provide 3D visualizations and accurate quotes in minutes.

Get Help NowOrder Now 866-761-7225

Questions or Need a Quote?

Chat live with a knowledgeable and friendly safety expert now.

Bob Kashtan

Located in South Carolina

Joey Robinson

Located in South Carolina

Caelin Lacy

Located in South Carolina

Katie Kelly

Located in South Carolina

Amber Graham

Located in South Carolina